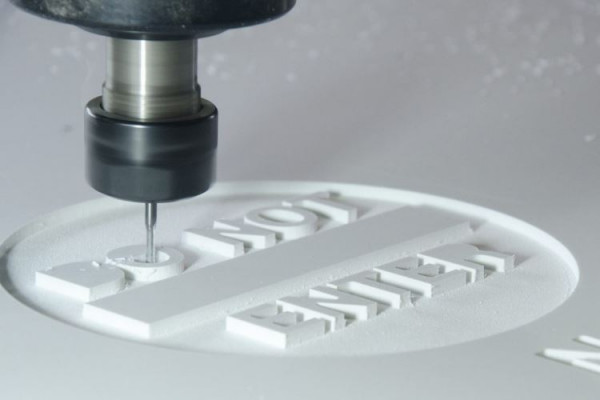

Milling plastic on CNC machines. Specificity. Models.

Plastic is the most popular material today. This is due, first of all, to its favorable price. Products made from various types of plastics can be produced on CNC machines or 3D printers. Today we will dwell in more detail on the features of plastic milling, how it is done, what is worth considering, which cutters should be chosen.

You can order a 3D model for manufacturing a plastic product on a CNC machine from us. A huge range of ready-made models is presented. There is a possibility of development according to an individual project.

Features of plastic as a material for milling:

The milling machine is suitable for processing not only wood, stone, foam, gypsum, but also for working with plastics. With its help, a variety of products are created from plastic. Among them are souvenirs, advertising structures, decorative items, huge letters, signs, some toys, grilles, panels, frames, stands, boxes, art objects and so on. Plastic is also suitable for creating molds for filling. In general it is possible

Plastic is a malleable material, does not require high loads, special cutters, and is not fragile. However, plastic milling has its own characteristics. By following the recommendations, you can get high-quality products in the shortest possible time.

You should also consider the type of plastic. Because today there are a huge number of different plastics, differing in color, density, and thickness.

Recommendations for working with plastic on CNC machines:

- Firstly, due to the fact that plastic is a soft material, it is important to choose a cutting mode so that the workpiece is not exposed to high temperatures and does not overheat. In addition, the rapid movement of the cutter can lead to cracks on the surface of the workpiece or product. Therefore, most often the speed is set low, and the exact values are selected experimentally during preliminary penetrations.

- Chips are removed from the cutting zone using pressurized air.

- For durable types of plastic, diamond-coated cutters are used, which is due to the viscosity of the material; for other types of plastic, ordinary cutters or carbide cutters are used. Preference is given to a small tool sharpening angle.

- For most types of plastic cutting, single-flute cutters are used.

- For through cutting of plastic, it is recommended to use cutters with chip removal downwards (with a left helical groove).

- Working with end mills allows you to create precise grooves, protrusions and recesses in plastic.

- End mills are used for roughing work.

If chips, melted parts, or cracks form on a plastic product after milling, then the workpiece will be considered defective. You will need to change the cutting mode or tool.

Types of plastic:

When working with plastics, their type should also be taken into account.

For example, thermoplastics (PVC, polystyrene, polycarbonate, etc.) melt more easily, so when working with them, set the spindle speed to low, reduce the feed speed, try to cool the working area, use single- or double-thread cutters.

And thermosets (these include carbolite, phenoplast, polyurethane, etc.) are more resistant to heat and can be processed by dry milling. When working with them, four-point tools are often used.

Models:

You can buy 3D models for manufacturing plastic products on CNC machines on our website. We have a huge assortment.

You may be interested in the following sections:

- 3D panel models

- 3D models of lattice

- 3D models busts

- 3D models toys

- 3D models of cars

- 3D models insects

- And many others.

- See the entire range.

If you require the development of custom-made models, we are waiting for your applications. We produce models of any complexity. For CNC machines and 3D printers. We prepare as soon as possible. We guarantee high quality.

Call, write, ask questions on the website.

You may be interested in other articles on the site:

- Gypsum on CNC. Features of working with gypsum. Models for machine tools.

- Features of stone milling on CNC machines. Models.

- Milling and processing of foam plastic and expanded polystyrene on CNC machines. 3d models

- 2d and 3d models for CNC, differences, features